Aerospace and Defense

Customer Use Case: Aerospace and Defense

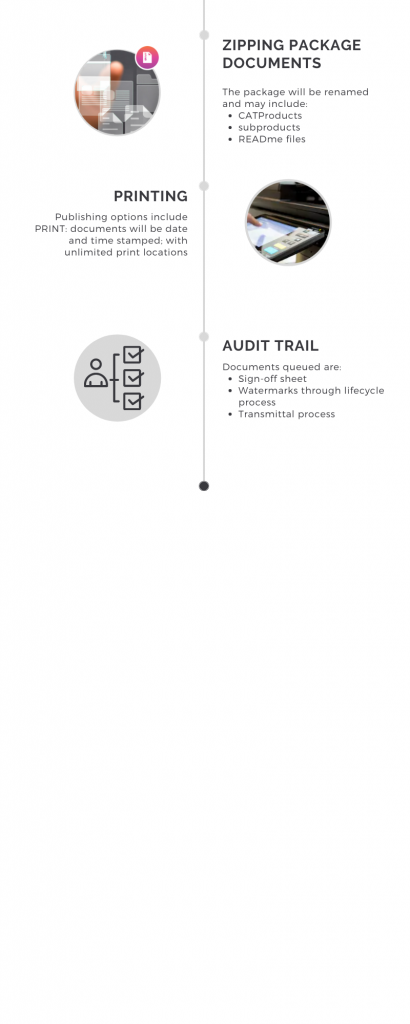

OCR / CONVERSION / STAMPING / CUSTOM DOCUMENT GENERATOR

CUTSOMER USE CASE

Download Qore8 Solution DataSheets

Learn how Qore8 solutions can layer with your existing systems to transform your business processes.

THE SMART, SECURE CORE OF

DIGITAL TRANSFORMATION

© 2020 Qore8

Created by Emily Sewell Privacy Policy Terms of Use Cookies

What Is the No Compromise Era?

| Apr 30, 2019 |

The pressure is on and it’s coming from every angle. The Aerospace & Defense industry faces growth in space, a huge backlog of commercial orders and increased spending in defense. Original Equipment Manufacturers and large suppliers demand greater efficiency from their suppliers. New competition in the form of manufacturers in emerging BRIC (Brazil, Russia, India and China) economies—made more agile by the latest technological innovations—wait hungrily in the wings, ready to replace those who fail to deliver.

In short, to thrive the industry must deliver more advanced aircraft, defense systems and space vehicles, in less time and at lower cost than ever before.

And yet, according to the paper, ‘Improve program execution with integrated simulation’ by Lifecycle Insights, a Product Lifecycle Management (PLM) analyst study states that only 18% of all Aerospace & Defense programs and projects are delivered on time without disruptive shifts in resources. The study shows that increased failures during prototype testing result in a decreased likelihood of launching programs on time. The conclusion: better insight into product and systems performance is “desperately needed earlier in the program cycle”.

So, how do companies improve program execution and first-time quality without compromising on quality and requirements? The answer is found in an enterprise digital ‘makeover’ that unites the many specialized disciplines needed to convert an idea into a 3D model. This model can be simulated, tested, refined and experienced, all in a virtual environment. Having a digital makeover provides the potential to balance all three critical legs of the quality, cost and time ‘stool’.

Applying simulation throughout the lifecycle

The Lifecycle Insights paper proposes an optimal combination: “The right mix of specialist and integrated simulation technologies can make a powerful difference… In concept design, these tools help define feasible bounds of performance. In contract bidding, they enable better-informed teams to bid more accurately, thus protecting profits. In detailed design, they provide engineers guidance on daily decisions, so that designs are more likely to pass prototyping and testing the first time. Even in prototyping and testing, simulation allows teams to understand secondary and tertiary failure modes… Simulation Intelligence systems provide insight across all types of analysis results plotted against different item configurations. Simulation data management tracks it all, managing files and configurations.”

This holistic approach to simulation—recognizing its huge value in verification and validation—and applying it throughout the entire lifecycle of the program, is where forward-thinking companies are heading.

Harnessing the power of collaboration

Simulation isn’t the only digital application offering major potential for an enterprise digital makeover. Platform-driven digital collaboration applications make it possible for teams across an enterprise or their extended enterprise to optimize designs and streamline processes while keeping a firm eye on costs.

Witness the success story of the Airbus A350 XWB program. Airbus programs suffered from duplication and lack of visibility because each location maintained its own digital mock-up and worked separately. This lack of communication extended design time and introduced errors that drove up costs.

Once Airbus put its development platforms under the single Dassault Systèmes ENOVIA application, its employees and extended enterprise accessed all relevant data and information in real-time, thereby reducing engineering change orders and keeping the A350 XWB program on course.

In addition to ENOVIA®, Airbus uses a range of Dassault Systèmes’ apps for design, simulation and manufacturing on the 3DEXPERIENCE® platform. The platform became the core enabler for the A350 XWB program credited by the company for meeting the maiden flight date.

“We had many challenges including a very aggressive development schedule and the need to ramp up production quickly to satisfy our delivery commitments,” explained Didier Evrard, Executive VP and Head of the A350 XWB Program.

“With 3DEXPERIENCE ®, our design quality and efficiency have considerably improved… We used CATIA to design the aircraft’s structure, the installation systems, the tubing, the composites parts, and the electrical systems completely in 3D,” added Evrard.

“With SIMULIA, we transitioned from an approximate, linear analysis approach to a more accurate, non-linear analysis, which gives us a deeper understanding of how the structure really performs in a given situation.”

“Making the A350 XWB possible presented tremendous technical, technological and organizational challenges due to the complexity of the program and the number of outsourced stakeholders. But with Dassault Systèmes’ solutions, we introduced harmony in our processes, methods and tools, and saved precious time that we spent, instead, on innovation.

Integrated system boosts performance

What do you do when your systems don’t work together? MBDA, a world leader in complex missile systems, had to confront issues caused by having stand-alone Enterprise Resource Planning (ERP), Manufacturing Execution System (MES) and PLM. This was no longer practical to support, nor was it compliant with current operating systems. Even worse, some MBDA sites were still using paper-based tracking systems.

An integrated solution was seen as the way forward: “Once we reviewed and understood Apriso’s FlexNet, it became clear that we could realize significant performance improvements and cost savings by integrating our enterprise planning, engineering and manufacturing operations systems,” said Jérémie Ropero, Project Manager. “Apriso’s solution handles the diverse products and types of controls we required while providing a strong foundation for tracking and tracing production and process changes.”

MBDA now has “superior reactivity between process design and the shop floor, making us more nimble,” according to Ropero. “This allows us to be more responsive to technical innovations, essential in such a fast-changing industry as ours.”

The company’s production and quality operations are fully traceable, while operators are more versatile. The routing definition procedure has been harmonized across departments (routing maintenance time has been reduced by 50%) and new information systems are linked with existing apps.

The company’s production and quality operations are fully traceable, while operators are more versatile. The routing definition procedure has been harmonized across departments (routing maintenance time has been reduced by 50%) and new information systems are linked with existing apps.

Searching for efficient analytics

If you want to accelerate your product to market, then you’ve got to speed up processes and reduce duplication. That’s what US-based Bird Technologies had in mind when it adopted Dassault Systèmes’ EXALEAD OnePart application to turbocharge their engineers’ search for similar parts and to reduce the number of duplicate parts in the database.

“Customers value the reliability of our products but also want good quality for less money,” explained John Winter, Mechanical Engineering Manager at Bird. “Our large product portfolio has resulted in a lot of 3D models that, if they could be reused in new designs, would considerably cut costs and market delivery time. Yet, the file locator tool we were using in the past was a non-indexed search tool that was slow and inefficient. Rather than wasting time waiting for the tool to crawl through all our data, our designers preferred redesigning components from scratch.”

Opting to redesign components also left Bird with a large database of duplicate parts on its server. “We had over 3,000 duplicate parts and needed a way to reduce this number,” Winter said. “Reusing existing designs was the answer.”

EXALEAD’s OnePart searches through the design database based on file attributes, metadata and geometric similarities, so Bird’s engineers can quickly find similar parts.

“We’ve realized a 75% reduction in duplicate parts and expect this to improve as more of our engineers get acquainted with this application,” enthused Winter. “Before, our engineers and especially new hires would ask one of their more experienced colleagues where they could find a certain part. Now my designers don’t need to depend on anyone; they use OnePart to search for the part themselves.”

Bird’s engineers also use OnePart for 3D CAD documents and for all other design documents, such as data sheets, test data, manufacturing instructions, test procedures and drawings. In fact, all their search processes have been completely transformed for the better. “Information search has been reduced from an average of four minutes per search to just a few seconds,” Winter added.

Understanding the value of digital transformation

Successful digital transformation goes hand in hand with a transformation of the way your organization works. Businesses should be prepared to break down traditional silos to embrace new ways of working seamlessly across functions, departments, languages and geographies. ‘Rework’ should become a thing of the past.

The PwC article, ‘2017 Commercial Aviation Trends’ by Jonathan Kletzel and Bryan Terry, points out that “a sense of urgency is required” for companies to move to a digital organization to cope with significant increases in passenger traffic. Nonethless, the authors accept that “moving beyond buzzwords like AI and IoT to actual applications can be difficult.” Rather than getting bogged down in the “shiny object” aspect of technology trends, Kletzel and Terry urge the industry to “think more practically: specifically, think in business terms about what digital technologies enable; what opportunities they offer to grow the top line and reduce operating costs simultaneously.”

For example, airlines need to use digitalization to “enhance and optimize operations—to reduce costs while improving service. They need to put technology to work in predicting and preventing equipment failures, in optimizing processes and productivity on the ground, and in providing better and timelier information to employees.”

The authors argue that those at the top of the management tree need to view digitalization in the right light. Instead of using it as a “panacea” or virtual band-aid, digitalization should serve as “a tool for tactical innovation”.

“Your business strategy—the company’s short- and long-term goals—will point the way to the customers you want to win, the offerings you hope to provide that attract these customers, and the right channels for reaching them. When those objectives are known, you can identify the technologies that best support them.”

Meeting—and exceeding—expectations

By embracing the digital transformation of your product lifecycle—concept, development through manufacturing, Aerospace & Defense manufacturers and suppliers can confidently build increasingly complex aircraft to meet passenger demand, operator cost and uptime targets.

Now it’s possible to work concurrently in the context of a full system digital mock-up which provides a single version of the truth. With this collaboration—everyone working together from different locations in real-time—you can deliver dramatic new efficiencies in design, validation, manufacturing, testing, certification and the ongoing support of new aircraft. And, program managers can continuously monitor schedules, budgets, resource allocation and deliverables across the supply chain.

This is the course to true operational excellence—accelerating complex program development, increasing productivity, optimizing component and system design via process automation, and maintaining total control of programs. You can ensure you meet contract deadlines, lower costs even further and, most important of all, that your customers always receive the quality they expect.

Download Qore8 Solution DataSheets

Learn how Qore8 solutions can layer with your existing systems to transform your business processes.

THE SMART, SECURE CORE OF

DIGITAL TRANSFORMATION

© 2020 Qore8

Created by Emily Sewell Privacy Policy Terms of Use Cookies

Harness Powers of Agility in Production

The Aerospace & Defense industry performs an exceedingly delicate balancing act between production and demand. Excess capacity lowers margins while insufficient capacity can cost millions in lost revenue.

As a result, manufacturers focus on dynamically matching their production rates with market pressures – simultaneously striving to improve first time quality, lower costs and ensure on-time delivery.

Companies have a high incentive to solve these challenges. The reported eight-year backlog in meeting commercial aviation ordersmay well double in the next 20 years. Add to that the significant ramp-up of defense spending, not to mention the commercialization of space, and you’ve got a big industry with a big problem. How should Aerospace and Defense companies capitalize on this unprecedented wave of demand?

Join the power of the digital revolution

Leading companies recognize the power of technology to fundamentally change the way they do business and meet today’s challenges. In particular, digital continuity is set to solve a multitude of production and product development challenges facing the industry.

Thanks to Industry 4.0, or the 4th Revolution, new technologies can combine the physical, digital and biological worlds. This changes the way A&D companies conceive, design and build products. It is possible to share 3D models across your enterprise and supply chain and communicate in real-time with no language barriers. Embracing this awesome new technological power can positively change a company’s future. Read more about the future factory.

Your path to the future

“Manufacturing traditionally has been thought of as a process that turns raw materials into physical products, and the factory as the structure where manufacturing happens,” Velocci adds. “Today the pervasive expansion of sensors and the Internet of Things (IoT), not to mention ever more demanding customers, are driving the transformation… Layered on top of this shift is the convergence of robotics, materials science and additive manufacturing, which are revolutionizing what can be manufactured and how.”

Velocci describes a brave new world of self-regulating machines: customizing the product builds, allocating resources in the most efficient manner, and interfacing seamlessly between the physical and virtual worlds of production and assembly. Wireless sensors in manufacturing equipment, processes and products provide real-time shop floor information – fuelling predictive analysis for those few remaining humans required to oversee the product lifecycle.

This new digital infrastructure encompasses old analog tasks and machine operations, while shifting the manufacturing process from isolated silos to integrated systems that work right across domains, hierarchical boundaries and lifecycle phases.

It follows that, if you stick rigidly to your existing vertical ecosystem, the new tools at your disposal won’t work. The real world might be round, but the working world is becoming very flat. Breaking down information silos fosters cross-functional cooperation, so everybody involved in a project can immediately access and use information as it becomes available. This reduces wasted resources from not having the right data at the right time – therefore leading to productivity gains.

Defining the power of digital continuity

To get onboard with the concept, companies must explore what is really meant by ‘digital continuity’ and its importance to the future of both their enterprise and the industry. Read more about digital continuity.

“In the 21st century economy, we cannot afford to not know that the version of design we are using has been obsoleted by a newer design,” argues Grieves. “We cannot afford to have engineering send designs to manufacturing that manufacturing knows cannot be built properly or cost-effectively. We cannot afford to not know what machine-to-machine communications are occurring that will result in a major manufacturing failure.” This ‘knowing’ information across the product lifecycle has become critical as information has gone from being on physical pieces of atom-based paper to digital bits.

“Therefore, the idea of digital continuity is that we are dealing with digital information that has a characteristic of singularity and that no matter where it is used in the lifecycle, it can be relied on as unique, authoritative, current and consistent. If we implement digital continuity correctly, we have all the advantages of the singularity of paper documents, but with the instantaneous and simultaneous ability to access the latest, updated information.”

Implementing the future factory

So, how do you transform the theory of ‘certain, singular real-time knowledge’ into the working reality of your future factory?

That requires a production system to provide a foundation to collaboratively model, simulate, operate and optimize your manufacturing. In addition, your company needs to ensure that its systems possess the automated means to secure sensitive product data and processes that underpin your market offering, as well as protect customer data. Those systems will also need to manage the flow of regulated data that meets, for example, the United States International Traffic in Arms Regulations (ITAR) and other export regulations.

Some companies have taken the lead and fully embraced the digital revolution with great success. For example, Messier-Bugatti-Dowty, the world’s leading manufacturer of aircraft landing and braking systems, is increasing manufacturing agility throughout production using a software solution from Dassault Systèmes on the 3DEXPERIENCE® platform.

The 3DEXPERIENCE platform provides the digital continuity needed to meet production rate and quality goals. It connects planning to the shop floor through a ‘digital twin’, so management learns about – and can immediately react to – potential issues in real-time. This power to foresee the future and correct errors before they become real problems results in higher production rates.

Beat inefficiencies with digital superpowers

Digital transformation gives organizations the ‘superpowers’ to take on the villains of wasted time and inefficiency that rob you of productivity and innovation.

With the ability to see issues in real-time and even foresee future possibilities and problems – through previously invisible patterns in data – you give yourself a competitive advantage with the power to:

- Optimize end-to-end manufacturing processes and supply chains before production ever starts.

- Test products virtually to deliver Six Sigma quality in the physical world.

- Design and develop aircraft digitally – fixing mistakes on a digital twin so it’s built right first time.

- Validate optimal configuration to meet requirements – on time and on budget.

- Share information with global teams in real-time to leverage best practice.

- Collaborate and work as one team – erasing barriers of distance, language and culture.

- Plan ahead for innovation and control global manufacturing to increase production / delivery rates.

Matching production with demand is possible

Every one of those technological powers transforms your company into a faster, better and stronger business. More agile in every way. Better still, these powers can be yours by embracing industry 4.0 and founding your own ‘Future Factory’.

You can improve decision-making – staying on budget and on time through 360 degree planning, simulation and instant insights.

You can enhance manufacturing quality and planning – meeting budget targets and contract deadlines.

You can integrate your suppliers with full traceability and track quality issues in real-time.

And then you can continue to strengthen your manufacturing prowess with unified change management, simplified certification and much more.

Indeed, as every proper superhero would say, you can’t stop doing good once you start. The power of success is addictive.

Ready to see how Qore8's Business & Compliance tools will help you simplify complex processes?

Learn how Qore8 solutions can layer with your existing systems to transform your business processes.

THE SMART, SECURE CORE OF

DIGITAL TRANSFORMATION

© 2020 Qore8

Created by Emily Sewell Privacy Policy Terms of Use Cookies